Why Powder Coating is the Best Choice for Wheel Refurbishment in Canvey Island

For Canvey Island drivers who want to extend the life of their alloy wheels while improving their appearance, powder coating is one of the most effective and long-lasting options available. This advanced finishing technique provides a durable, attractive, and fully customisable solution, making it a standout choice for alloy wheel refurbishment in the area.

In this guide, we explain what powder coating is, its benefits, the process involved, and why it outperforms traditional paint finishes.

What is Powder Coating?

Powder coating is a specialist finishing process in which a fine, dry powder pigment is applied electrostatically to the surface of the wheel. The powder adheres to the metal and is then cured in an oven, melting into a smooth, hard-wearing finish.

Unlike conventional paint, powder coating is far more durable, offering exceptional resistance to chips, scratches, and fading. It’s also an eco-friendly option, as it releases virtually no volatile organic compounds (VOCs) and produces minimal waste.

Benefits of Powder Coating for Canvey Island Drivers

1. Durability and Longevity

- Resistant to Damage – Powder coating can withstand everyday road hazards, from stone chips to kerb scrapes, far better than traditional paint.

- Weather Protection – Canvey Island’s coastal climate, with salty air and wet winters, can cause corrosion. Powder coating creates a strong barrier against rust and environmental damage.

- Low Maintenance – The smooth, sealed finish makes cleaning quick and easy, with dirt and brake dust less likely to stick.

2. Customisable Finishes

- Wide Range of Colours – From classic silver to bold metallics, powder coating offers a huge variety of shades and finishes.

- Stylish Options – Choose from matt, satin, or gloss finishes to achieve the exact look you want.

3. Environmentally Friendly

- Eco-Conscious Choice – Powder coating produces little waste and contains no harmful solvents, making it a sustainable option for environmentally aware motorists.

4. Cost-Effective

- Long-Term Savings – Its durability means fewer touch-ups or resprays, saving money over the life of the wheels.

- Extended Wheel Life – Protects against corrosion, reducing the need for replacements.

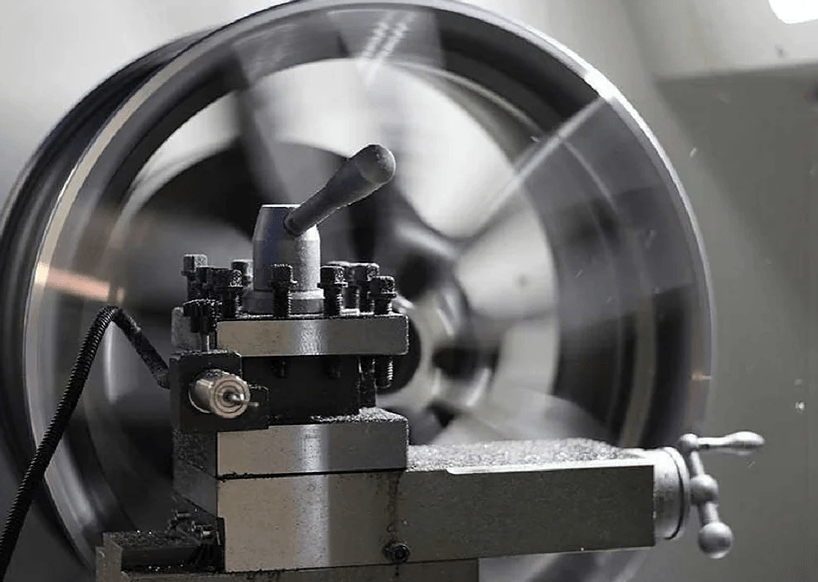

The Powder Coating Process

A professional powder coating service in Canvey Island follows a precise process to ensure a flawless result:

1. Wheel Preparation

- Cleaning & Sandblasting – Removes all traces of dirt, old paint, and corrosion for a perfectly smooth surface.

- Inspection – Checks for cracks, bends, or other damage, with repairs carried out before coating.

2. Powder Application

- Electrostatic Spray – Charged powder is sprayed evenly over the wheel, ensuring complete coverage with minimal waste.

3. Curing

- High-Temperature Baking – The wheel is placed in an oven at 160–200°C, melting the powder into a seamless, tough layer.

4. Cooling & Final Checks

- Cooling – The wheel cools naturally, solidifying the finish.

- Inspection – Every wheel is checked for an even, flawless coating before being refitted.

Powder Coating vs Traditional Painting

When compared with liquid paint, powder coating has clear advantages:

- More Durable – Better resistance to chips and scratches.

- Weather-Resistant – Maintains colour and finish despite coastal conditions.

- Cost-Effective – Lasts longer, reducing the need for frequent refinishing.

- Eco-Friendly – No VOC emissions and minimal environmental impact.

Why Choose Powder Coating in Canvey Island?

With local roads and weather conditions putting alloy wheels to the test, powder coating offers Canvey Island drivers a strong, attractive, and practical solution. It not only improves appearance but also protects against the salt, moisture, and general wear that coastal driving can cause.

For a finish that’s as stylish as it is strong, powder coating is the premier choice for alloy wheel refurbishment in Canvey Island, Essex.