How to Repair Cracked Alloy Wheels: Wheel Refurbishment in Canvey Island, Essex

Alloy wheels are a popular choice for motorists thanks to their lightweight construction, modern styling, and performance benefits. However, they are also prone to cracking, especially when exposed to potholes, kerb impacts, or other road hazards.

For Canvey Island drivers, a cracked alloy wheel is more than just a cosmetic problem – it can compromise safety, cause handling issues, and shorten the life of your tyres. Fortunately, professional wheel refurbishment services in Canvey Island can repair many types of cracks, restoring both appearance and performance.

Why Alloy Wheels Crack

Alloy wheels, typically made from aluminium or magnesium, combine strength with reduced weight. However, unlike steel wheels, they have less flexibility and are more susceptible to cracking under sudden impact. Common causes include:

- Potholes and Road Damage – Coastal roads in Canvey Island can deteriorate after bad weather, with potholes posing a significant risk to wheels.

- Kerb Impacts – Parking mishaps or sharp turns into kerbs can cause cracks, particularly if the wheel is already weakened.

- Temperature Changes – The expansion and contraction caused by seasonal temperature fluctuations can gradually weaken wheel structure.

- Low Tyre Pressure – Under-inflated tyres absorb less shock from road impacts, transferring more stress to the wheels.

Risks of Driving with a Cracked Wheel

Ignoring a cracked alloy wheel can lead to serious consequences, including:

- Loss of Strength – A cracked wheel is weaker and more likely to fail at speed.

- Vibrations and Imbalance – Damaged wheels can cause uncomfortable vibrations and affect handling.

- Increased Tyre Wear – Uneven pressure distribution from a cracked wheel accelerates tyre wear and increases the risk of blowouts.

How Professionals Repair Cracked Alloy Wheels in Canvey Island

A reputable wheel refurbishment specialist will follow a detailed process to restore strength and appearance:

1. Inspection and Assessment

The wheel is removed and carefully examined to determine whether repair is safe. Small, localised cracks are often repairable, but damage to critical areas such as the mounting points may require replacement.

2. Cleaning and Preparation

The wheel is thoroughly cleaned, often using sandblasting, to remove dirt and corrosion. The crack area is then ground back to prepare it for welding.

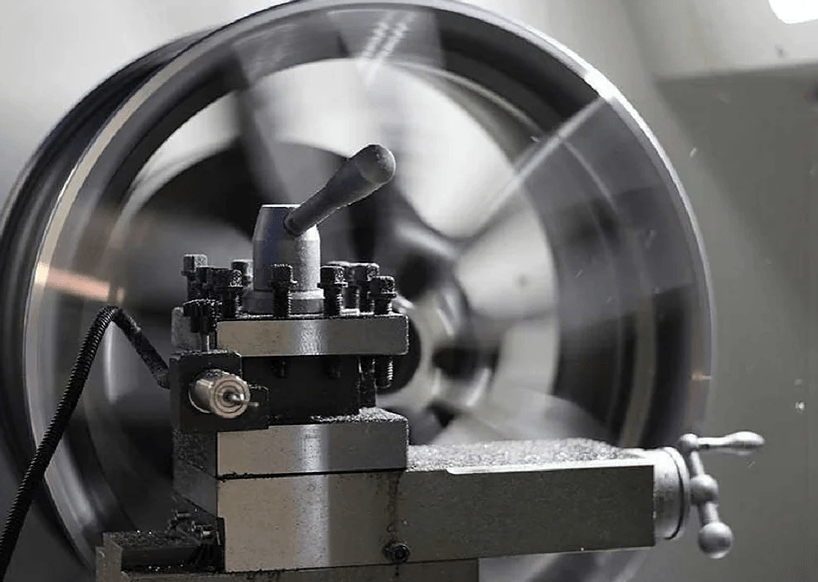

3. TIG Welding

Tungsten Inert Gas (TIG) welding is used to fill the crack with a compatible alloy, ensuring a strong bond and minimal heat damage.

4. Smoothing and Reinforcement

Once welded, the area is smoothed to match the wheel’s original profile, and the repair is checked for strength and integrity.

5. Cosmetic Restoration

To restore the wheel’s appearance, it may be repainted or powder coated. Powder coating is particularly durable and offers excellent corrosion resistance – ideal for Canvey Island’s coastal environment.

6. Balancing and Final Checks

The wheel is rebalanced to ensure smooth performance before being refitted to the vehicle.

Benefits of Professional Crack Repairs

- Restored Safety – Proper welding restores the wheel’s structural strength for safe driving.

- Cost Savings – Repairing a wheel is often far cheaper than replacing it, especially on high-end vehicles.

- Improved Appearance – Cosmetic refinishing leaves the wheel looking as good as new.

- Better Performance – Eliminates vibrations, improves handling, and extends tyre life.

- Eco-Friendly Option – Repairing rather than replacing reduces waste and supports sustainable vehicle care.

When Replacement is the Only Option

If cracks are severe, widespread, or located in critical load-bearing areas, repair may not be safe. In these cases, a professional will recommend replacing the wheel to maintain road safety.

Conclusion

Cracked alloy wheels are a common problem for Canvey Island drivers, particularly given local road conditions and the coastal climate. Left untreated, they can compromise safety, damage tyres, and reduce driving comfort.

By using a trusted Canvey Island wheel refurbishment service, you can restore your alloy wheels quickly and cost-effectively – ensuring they look great, perform well, and keep you safe on the road.

Don’t ignore a cracked wheel – get it inspected and repaired by an expert before it becomes a costly replacement.